Here is an article written by our engineering team that will guide you on the most common material choices that our customers have to make. The material choices made when you prototype something are influenced by the end application of the part. Some examples are whether the part is a form-fit prototype, production prototype or a feasibility prototype.

Al 6061 is the most common type of Aluminum that is used for both prototyping and precision machining application(s) for mass manufacturing. Perhaps one of the most versatile materials available thanks to its impressive strength-to-weight ratio (Ultimate Tensile Strength of 290 MPa), but more prominently, ease of welding over other types of Aluminum. As a result of it being easily machinable, it is widely used as a construction material, most commonly in the manufacture of automotive parts, architectural components and other miscellaneous components that are used in a variety of day-to-day items. As Al 6061 extrusions are widely available, many structures make use of lathed and/or cut extrusions welded into place. This is a relatively cost-effective means of manufacturing an entire structure without high-cost methods such as machining.

The main difference between Al 6061 and Al 7075 is the tremendous increase in tensile strength. Al 7075 has one of the highest strengths of commercially available forms of Aluminum (Ultimate Tensile Strength of 572 MPa). Albeit it’s low weldability, it’s low density and high strength makes it ideal for high performance components where strength is critical, but weight savings are also prioritized. Therefore, Al 7075 is widely used in the aerospace industry, defense applications and many mechanical components which undergo high stresses such as gears, shafts and worm gears.

Al 7075 Aerospace Framework

Al 5052 exhibits a much higher workability over Al 6061 allowing it to be formed into intricate shapes. It also has a high fatigue strength with excellent resistance to marine conditions and saltwater corrosion. Hence, Al 5052 can be seen predominantly used to make failure-sensitive components for marine, highway and fuel tanks. Al 5000 series grades are therefore used mainly to make sheet metal components which are formed into the shape required for the use. You can learn more on how sheet metal design and tolerancing on our article available here:

Tolerance Guidelines for Sheet Metal Design .

Due to the low carbon content, the products made from mild steel are not very brittle nor ductile in addition to being cost-effective and easy to manufacture, making it a very versatile metal so much that you would find it being used everywhere. Mild steel has an especially high strength and is therefore highly favored in the construction industry, especially for steel frame buildings. By adjusting the carbon content, the strength, ductility and hardness can be adapted as desired, causing mild steel to be preferred for machinery part manufacturing. It has also been the material of choice for pipelines and aesthetic gates and fencing thanks to mild steels impressive resilience to weather, ease of welding, durability and low maintenance.

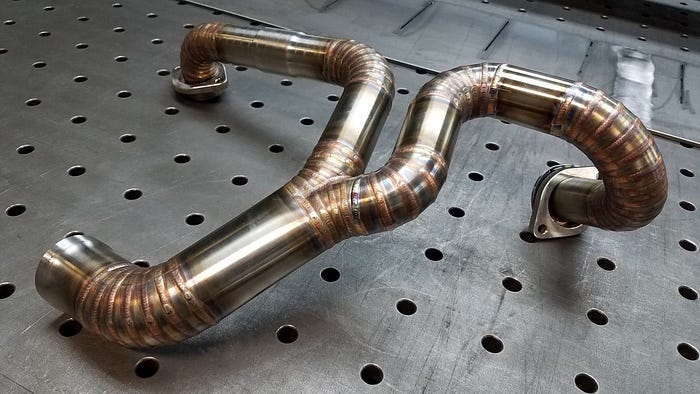

With corrosion resistance as its star property, stainless steel is known for its high tensile strength, temperature resistance, recyclability and attractive finish. It can be easily welded, the austenitic forms (such as the most common AISI 304) being the easiest, making it ideal for architectural structures and automotive components. Due to its surface finish allowing for easy cleaning and extensive resistance to chemicals, stainless steel is widely used in medical apparatus, food production systems, cutlery and kitchenware. However, it is harder and expensive to manufacture making it a high-cost material and hence underutilized in many industries.

Stainless Steel Automotive Manifold

Acrylonitrile Butadiene Styrene is a high-impact thermoplastic with high rigidity, strain resistance and weldability. It is ideal for both electrical and mechanical components to be made via injection molding or extrusion. ABS can be easily molded compared to the plastics and creates a clean finish which is easier to paint, machine, sand and glue. This along with its low cost makes ABS an ideal material for prototypes. Due to its low melting point and relatively high strength, it is widely used to 3D print prototypes and functional parts using FDM technology. To learn more about FDM and other methods of 3D printing, do read our whitepaper on 3D Printing technologies available here: 3D Printing Technologies