Here is an article written by our engineering team that will guide you on how to make the most out of your design experience. We hope to give you a succinct yet complete depiction of the different kinds of 3D Printing technologies available. This would help you optimize your design to ensure that they can perform the intended role best!

To someone who hasn’t seen a 3D printer, seeing one for the first time is absolutely magical! The ability to create a physical part you’ve designed out of a roll of filament or a bottle of resin, seems like science fiction. In layman terms, 3D printing refers to constructing a 3D part of a digital design. There are many ways to 3D ‘print’ something, but some of the more popular processes definitely have things in common.

For starters, they’re all (mostly) additive processes. This is in sharp distinction to conventional manufacturing processes such as milling or turning which are subtractive processes. In the former you build parts from ground-up, and in the latter, you break of chunks from a larger block to get to the desired part. Both have advantages in terms of the quality, cost, strength and parts that can be manufactured. The user may need to decide on a process based on his/her requirements. Needless to say, 3D printing has significant use cases in prototyping due to the short lead time and cost for high-mix, low-volume parts. It is also extensively used in the medical, aviation, automotive, construction and healthcare sectors.

All 3D printing processes use filaments, which act as the building block, to construct parts from the ground up. In our segregation of the processes, we’ve classified them based on the type of filament/raw material used, followed up by a bonus section of metal 3D printing.

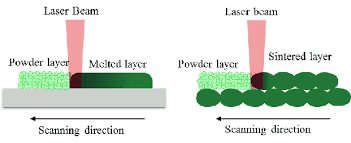

In SLS, layers of powder-based filaments are deposited, partially melted and cured. This leads to a process that helps create complex geometries and forms. The process itself, involves the deposition of a layer of powder-based filament that is subsequently cured by a CO2 laser beam. A significant advantage being that no support structures are needed since the powder filament itself acts as a pseudo-support structure. Surface finish is rough and may require additional polishing and strength is weak, unless the part is infused with other substrates. But where SLS lacks some features, it makes up for in the ability to create complex geometries, minimum material wastage and the availability of a variety of raw powder filaments; even including metal alloys.

SLS Printed Parts

Like SLS, SLM also uses a powder based filament, to make parts from the ground up. The core difference between SLS and SLM is that in the former, the powder is sintered, and in the latter its melted. Sintering refers to heating a sample close to its melting point that allows particles to stick to each other. Melting on the other hand refers to heating the substrate above its melting point before curing. SLM has better material strength compared to SLS due to lesser air gaps, but tolerances and dimensions are more difficult to control due to non-uniform heating and cooling.

SLS (left) v/s SLM (right) 3D Printing

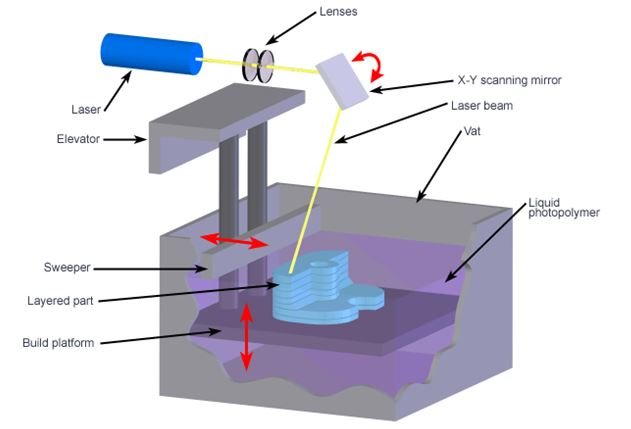

SLA uses a photopolymer resin that is deposited and cured layer by layer. Parts printed using SLA have excellent surface finish and quality due to the relatively thin layers of material deposited at a time. The process itself consists of a base plane, dipped into a vat of resin, that helps build up the parts. The biggest advantage of an SLA printer is that prints are extremely quick, and quality is excellent. The users can choose from a range of colors and materials, even transparent/translucent ones.

SLA 3D Printing

A disadvantage of SLA printing is that the parts may need to be cured/cleaned after fabrication due to support structures and/or support material and the resin is extremely toxic. These makes SLA a fast, process with excellent surface finish. but with added cost and thus criteria must be weighed before choosing it.

SLA Printed Parts