Here is an article written by our engineering team that will provide you 4 tips that will help you design sheet metal parts. Sheet metal can be shaped into a myriad of shapes due to its flexibility as explained in our previous article here: Tolerance Guidelines for Sheet Metal Design . However, certain design considerations must be kept in view when designing for sheet metal fabrication. The following tips are not meant guidelines differ from manufacturer to manufacturer. dependent on skills and machinery available.

To start, we need to be considerate of the distance between features as placing them too close to each other would result in inaccuracies and increased cost to make up for the poor design.

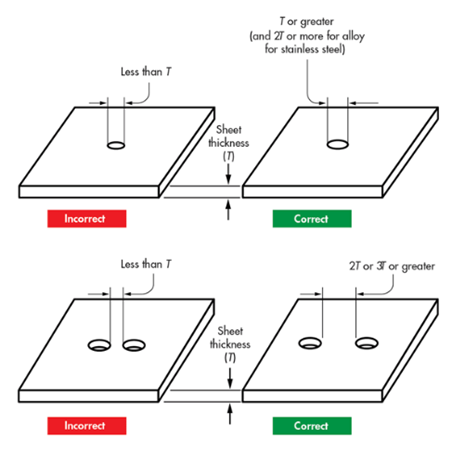

Acceptable distance between extruded holes

Acceptable distance from edge to extruded hole

This is to prevent deformation or tearing of the edge and the hole because of the shearing process when making the holes. Further details can be found in another article that we’ve written here.

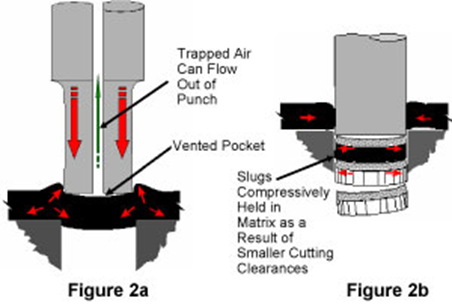

Holes should be wider than the sheet’s diameter as seen below. While this is not mandatory, following this tip would help with cost savings. This is because additional post processing steps are required to remove the excessive burrs due to the higher punching load. Additionally, the lifespan of the part would decrease due to slug pulling as the punch is withdrawn as seen below.

Recommended design guideline for holes

Process of forming a hole

The distance between the 2 holes should be not smaller than the thickness of the sheet as seen below. This is to ensure the holes would not be deformed during the manufacturing process which would result in a need to have additional machining processes and thus increase cost for consumers. A more in depth article covering the cause of the issues can be found here.

The inner radius is generally at least 1 X the thickness of the metallic sheet. As the inner bending radius increases, the amount of strain on the edge decreases. This reduces the risk of cracking not only during the manufacturing stage but when in use as well. Cracks are formed when the stress is larger than the ultimate tensile stress, this means that ductile materials would require a smaller radius to achieve the same level of risk compared to a brittle material with a larger bending radius.

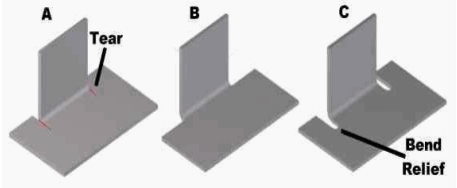

When bending non-homogenous, it is important to have sufficient distance between the edge and the formation of the bend to ensure Tearing does not occur (Part A). This should not be less than the radius of the bend.

However, when bending non-homogenous parts, Bend relief is a good way to relief the stress of the part as seen below (Part C) if your part requires the distance to be less than the radius of the bend.

Image showing location of stress and bend relief